In fact, in more than 90% of the installations where the maximum load can be determined, the actual line size is 1-3 pipe diameters too large or oversized for that load. Wouldn’t that just be the line size of the piping of where it will be installed? Unfortunately, this is not the case. In order to properly size a vortex meter you need to know the maximum flow rate or load expected. Why would someone select an over sized meter knowing it has a finite low flow cut-off? The first thought that comes to mind is a logical question: To make the problem worse, depending on how the meter was initially sized for the application (oversized in most cases), 15% to 50+% of the actual load or flow could still be passing by the meter while the meter has no vortices to measure! That is, unless a fixed output is configured into the output circuit (which is more common than not by some manufactures) to make the meter read some value. This means the meter has nothing to measure and, therefore, goes to zero. Also, keep in mind that at the meter’s low velocity point-which is Reynolds number dependent on where the medium (steam) goes from transitional to laminar flow- the shedder bar no longer sheds vortices.

These ranges will vary with the technology, but as a rule of thumb, Vortex meters are very linear and repeatable to +/-1.0% of rate or reading with a typical ideal meter turndown range of 20:1. Once vortices are shed, a pickup or sensing technology detects the vortices and the rate at which they are sensed is proportional to velocity.ĭepending on the sensing technology employed, any particular vortex meter will have a maximum and minimum velocity range. Vortex shedding uses a blunt body (called a shedder bar) inserted into the flow stream to create vortices as the flow passes over/around the shedder bar. Combined with available measurement technologies, you are very limited in a reliable, accurate measurement solution.Īs a general rule, the most accurate and reliable technology available for this application is Vortex shedding. You’re also working with compressibility/density changes due to pressure/load variances and operating ranges that have extreme variations depending on the time of the year/season. However, when you start to look at the measurement technologies available and the difficulties presented in measuring a compressible medium it becomes questionable if this side is, in fact, the most appropriate measurement location.ĭue to the nature of the process (Steam) you are faced with a very hostile medium with extremely high temperatures. The simple answer would be the steam side since this is the heating medium providing the energy to the point of use location. The Steam PI seems to have a slightly darker color.To calculate energy usage and loads for a heating system, the question is: Which side of the heating system should we measure to provide the most accurate and encompassing measurement results? Let’s start with an example from my roast with and without Steam PI. So I looked at two sample sets which show what I have been experiencing in general. I’d like to understand the technique better. I looked at some sample data because I don’t quite feel ready to do a set of paired shots. Total Dissolved Solids (TDS) is measured using a refractometer, and this number combined with the output weight of the shot and the input weight of the coffee is used to determine the percentage of coffee extracted into the cup, called Extraction Yield (EY). My aim was to be consistent for each metric, but some times the granularity was difficult. These scores were subjective, of course, but they were calibrated to my tastes and helped me improve my shots.

I used two sets of metrics for evaluating the differences between techniques: Final Score and Coffee Extraction.įinal score is the average of a scorecard of 7 metrics (Sharp, Rich, Syrup, Sweet, Sour, Bitter, and Aftertaste). Other Equipment: Atago TDS Meter, Acaia Pyxis Scale Metrics of Performance Shot Preparation: Staccato Tamped and Staccato

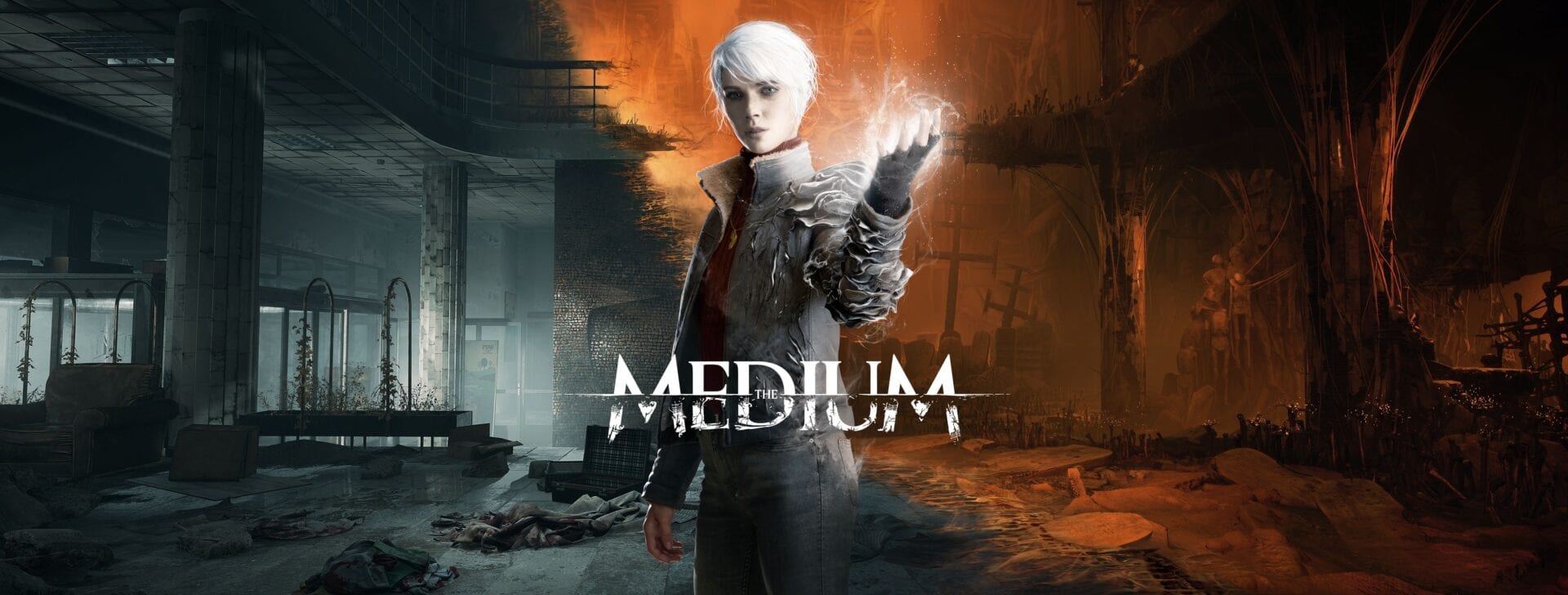

#THE MEDIUM STEAM CRACK#

Equipment/TechniqueĮspresso Machine: Decent Espresso MachineĬoffee: Home Roasted Coffee, medium (First Crack + 1 Minute)

#THE MEDIUM STEAM HOW TO#

I continue to test the variable so I can better understand how to use it. I have modified the Steam PI length based on the coffee I’m brewing. I also noticed the water temperature doesn’t fall off as quickly as with my starting profile. The measurement in the DE definitely measures a higher puck temperature, but that is measured at the top. This depends on the temperature of your boiler. I also looked at the time length for steam PI.

0 kommentar(er)

0 kommentar(er)